What Is The Purpose Of A Control Chart?

SPC FAQ

Just getting started? Here are answers to some of the most common SPC questions asked past those who have heard near SPC and want to learn more.

What is Statistical Process Control?

Statistical Process Control, commonly referred to as SPC, is a method for monitoring, controlling, and improving a procedure through statistical assay. The philosophy states that all processes exhibit natural variation, or randomness. However, sometimes processes exhibit excessive variation that produces undesirable or unpredictable results. In a manufacturing context, the less consistent and anticipated a procedure is, the higher its costs are. SPC is used to reduce variation and lower costs.

What is real-time SPC?

Today's manufacturers rely heavily on a combination of automation, mechanism, devices and technology in an effort to produce products faster. Equally manufacturing capacity increases, manufacturers require a method to increase their quality control capacity while shrinking the organization'due south overall price-of-quality. Traditional SPC allows manufacturers to empathize what products and processes were in-command or out-of-control. Even so, for some manufacturers this information comes also little, too late.

Real-time or in-line SPC is divers equally the technique of applying SPC on the shop floor at the fourth dimension of product. Existent-time SPC gathers product and process information in real-time and provides operators and plant managers with alerts, triggers, and other event direction tools to chop-chop contain and fix defects before they get out the shop floor.

Most continuous improvement, Six Sigma and lean manufacturing initiatives crave some course of SPC. While some programs focus on quality assurance, others focus on process optimization. Both existent-time SPC and SPC are viable programs for improving manufacturing production and process quality. Withal, existent-time SPC offers manufacturers a method to concurrently ameliorate product and process quality and lower the cost-of-quality. Similar to the benefits that a calculator offers the mathematician, automatic, existent-time SPC provides manufacturers with a bacteria method to continuously improve their product and procedure quality.

Where did SPC originate?

The foundation for Statistical Process Control was laid by Dr. Walter Shewhart working in the Bong Telephone Laboratories in the 1920s conducting research on methods to better quality and lower costs. He developed the concept ofcontrol with regard to variation, and came upwards with Statistical Process Control charts which provide a simple way to determine if the process is in control or not. Dr. W. Edwards Deming built upon Shewhart's work and took the concepts to Japan following WWII. At that place, Japanese industry adopted the concepts whole-heartedly. The resulting high quality of Japanese products is world-renowned. Dr. Deming is famous throughout Nihon. Today, SPC is used in manufacturing facilities effectually the world.

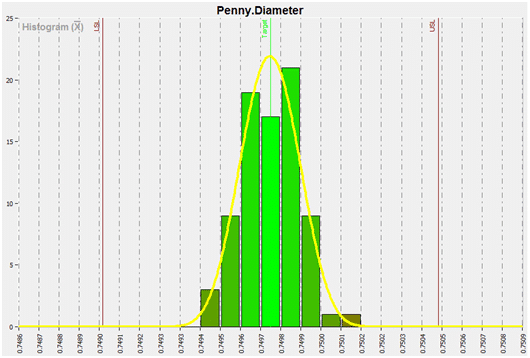

What is a histogram?

A histogram is a bar graph. Each bar shows the number of data points that fall within its measurement range. The relative heights of the bars offer clues to the health of a process.

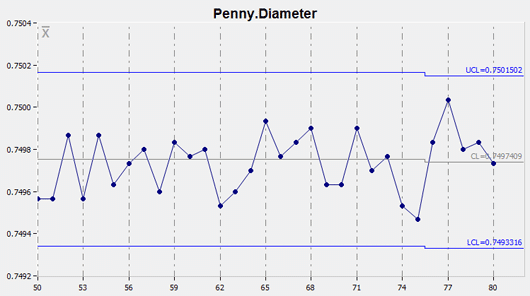

What are control charts?

Control charts consist of product or process measurements over time and are a graphical representation of the variation between those measurements (or between subgroups of those measurements). Some additional horizontal lines representing the average measurement and command limits are frequently drawn beyond a command chart. Likewise, notes virtually data points and limit violations are commonly displayed.

Command charts have four key features: 1. Data points are either averages of subgroup measurements or individual measurements plotted on the x/y centrality and joined past a line. Time is always on the ten-axis. 2. The Average or Heart Line is the average or hateful of the data points and is drawn beyond the middle section of the graph, usually as a heavy or solid line. 3. The Upper Command Limit (UCL) is drawn above the centerline and often annotated as "UCL". This is sometimes called the "+3 sigma" line. 4. The Lower Control Limit (LCL) is drawn below the centerline and oftentimes annotated as "LCL". This is sometimes called the "-3 sigma" line.

What is the purpose of a control chart?

It helps quality teams monitor how a process is performing and placespecial orassignablecauses for factors that impede peak operation.

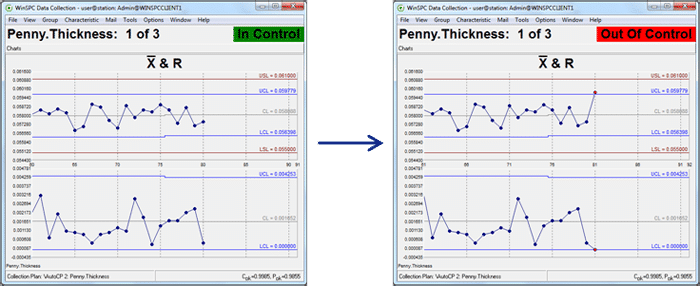

How practice they work?

Control charts show if a process isin control orout of control. They show the variance (or variation) of process output over time. Control charts compare this variance against upper and lower limits to see if it fits within the expected, specific, predictable andnormalvariation levels. If then, the process is consideredincontrol and the variance betwixt measurements is considered normal random variation that is inherent in the process. If, however, the variance falls outside the limits, or has a run of non-natural points, the process is consideredoutofcontrol.

What's this relationship between variation and assignable causes?

Variation is the fundamental to statistical process command charts. The extent of variation in a process indicates whether a procedure is working as information technology should. When the variation betwixt the points is big enough for the process to be out of control, the variation is adamant to exist due to not-natural orassignable (special) causes.

So how are these normal, predictable, variance levels determined?

The process itself determines the control limits. The command limits are automatically calculated from the data produced past the process. Control limits are the "voice of the process". They are non specifications, corporate goals, or the "vocalism of the customer". These two concepts must never be confused.

What aboutruleviolations for determining if a series of points within the control limits is unnatural?

The work done past Shewart and his colleagues gave them a base of empirical noesis on which to base rule violations. An example of a rule violation is vi points in a row steadily increasing or decreasing. Rules such as this have been codified and are contained in the AT&T Statistical Quality Control Handbook. SPC software tin can be used to automatically cheque for violations of these time-tested and industry proven rules.

What's the significance ofin-control andout-of-command?

If a procedure is in-control, the outcomes of the process can be accurately predicted. In an out-of-command process, at that place is no way of predicting whether the results volition meet the target. An out-of-command process is similar driving a charabanc with brakes that may or may not work. If a process is out-of-control, you wait for the assignable causes that make it and then and attempt to eliminate them.

What does processcapabilityhateful?

Processcapabilitybut refers to what a process is capable of producing. Some processes might be capable of producing 100% of their output inside spec, others considerably less. Sometimes an organization's requirements, specifications, or goals are across what the process is actually capable of producing. In this case, either the process must be fabricated more capable or the requirements, specifications, or goals relaxed.

Can any type of process data be judged using control charts?

Processes which produce data that exhibits natural or common-cause variation will form a distribution that looks like a bell-curve. For these types of processes, command charts will provide useful data. If the data is non commonly distributed, does not class a bell-curve, the process is already out-of-command and so it is not predictable. In this example we must await for ways to bring the process into control. For case, the information may exist besides broad, using measurements from different work shifts that take unlike process outcomes. Organizing the data collection into rational subgroups, each of which could be in command, is the start step to using command charts.

How do I make a command chart?

In the by, creating command charts was a difficult process requiring statisticians and mathematicians to remember the formulas and actually calculate the various data points and control limits. Today, using SPC software and computers, control charts tin can be synthetic apace and accurately, freeing you to investigate and remedy the situations exposed past command charts.

When is the best time to start SPC?

Now! The central to SPC isaction . Rather than trying to discover the perfect methodology or waiting until you are an SPC expert, it is best to dive in and get started. Y'all tin can always brand adjustments equally you go forth. In nigh circumstances, the toll of poor quality and non-conformance is too neat to do otherwise.

What are the Western Electric Rules that make up one's mind whether or not a process is in-control?

The relevant Western Electrical Rules and the charts to which they apply are detailed in the below table.

| CHARTS | Western Electric Rules |

|

|

|

|

|

|

|

|

by Statit Software, Inc.

What Is The Purpose Of A Control Chart?,

Source: https://www.winspc.com/tag/what-is-the-purpose-of-a-control-chart/

Posted by: leecouseed.blogspot.com

0 Response to "What Is The Purpose Of A Control Chart?"

Post a Comment